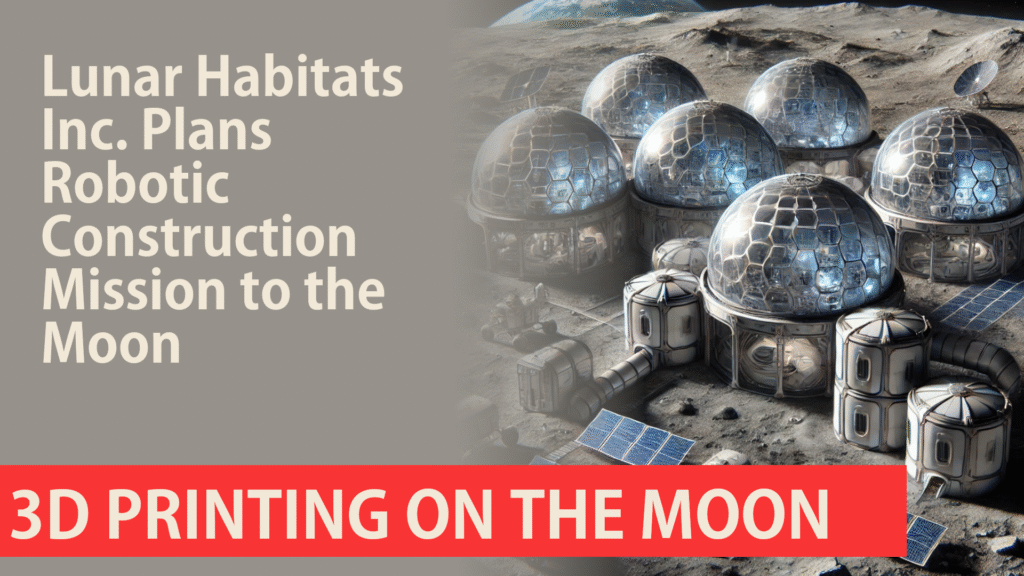

In a bold move that could redefine space colonization, a private aerospace startup, Lunar Habitats Inc., announced its plans to launch a team of autonomous robots and industrial-grade 3D printers to the Moon by late 2026. The mission, codenamed “Project Regolith Rise,” aims to use lunar soil—known as regolith—as the primary building material for permanent structures on the Moon.

If successful, the company will begin laying the groundwork for the first off-Earth human habitat constructed entirely from extraterrestrial resources.

From Dust to Domes

At the heart of Lunar Habitats’ mission is a radical innovation: the ability to 3D print entire buildings using nothing but Moon dust, solar energy, and robotic labor. The company has spent the last five years developing its proprietary Regolith Sintering System (RSS), which uses a combination of microwave sintering and additive manufacturing to fuse regolith into solid, durable layers—essentially “baking” Moon dust into bricks.

“Earth-based construction methods are heavy, expensive, and unsuited for the harsh lunar environment,” said Dr. Maya Rios, Chief Technology Officer of Lunar Habitats. “We’re flipping the script by building with what’s already there.”

The mission will deliver a suite of six autonomous robots, including excavation rovers, transport drones, and two towering “print crawlers” that will slowly extrude regolith-based structures on-site. All of it will be coordinated by an onboard AI guidance system, capable of adapting to terrain changes and lunar day-night cycles.

Launch and Logistics

The mission is set to launch aboard a SpaceX Falcon Heavy in Q4 2026, with the payload expected to land in the Moon’s southern polar region—an area of high interest due to its stable temperatures and nearby water ice deposits.

According to CEO Marcus Lee, this region was chosen not only for its scientific value, but because its fine-grain regolith is optimal for printing strong, insulating structures.

“Our ultimate goal is to establish Lunar Base Alpha, a fully robotic outpost that can build, maintain, and expand itself before humans even arrive,” Lee said.

Habitats for a Lunar Future

The first structures planned include a solar-powered operations center, a communications hub, and several shielded storage vaults. If the technology proves viable, Lunar Habitats plans to expand construction to include modular living quarters, radiation-shielded laboratories, and eventually, greenhouses capable of supporting small-scale food production.

The company is already in discussions with international space agencies, including ESA and JAXA, about future collaborations. A joint proposal for a semi-permanent human habitat—capable of housing four astronauts for 90-day missions—is currently under review.

Expert Skepticism and Cautious Optimism

While many in the space community are excited by the ambition, some remain skeptical.

“Printing on the Moon with regolith sounds great in theory, but the environmental variables—temperature extremes, fine abrasive dust, and communication delays—make it extremely challenging,” said Dr. Lydia Shore, a lunar materials scientist at Caltech.

Still, the potential upside is enormous. Eliminating the need to ship building materials from Earth could reduce the cost of lunar infrastructure by over 90%, and allow for scalable, sustainable settlements in space.

Next Stop: Home on the Moon?

Lunar Habitats Inc. represents a growing trend of private companies taking the lead in humanity’s next great leap. If Project Regolith Rise proves successful, it could mark a paradigm shift in how humans approach extraterrestrial living—not with flag-planting and temporary visits, but with long-term, self-sustaining infrastructure.

As Marcus Lee put it during the company’s press conference, “We’re not just landing on the Moon. We’re moving in.”